CUPROBAN Fully Automatic System for Antifouling and Corrosion Reduction

IMPROVED ELECTROLYTIC METHOD FOR PROTECTION AGAINST MARINE GROWTH FOULING OF SEA CHESTS, PIPELINES, STRAINERS, VALVES, CONDENSERS AND ALL SEAWATER SYSTEMS

WHAT CUPROBAN DOES:

Fouling is all to familiar to operators of seawater systems on ships, rigs, oil platforms, power stations and elsewhere. Marine growth, such as mollusca, algae and slime enter the seawater system and find a spot where temperature, nutrients, pH factor and other environmental conditions are right for settling and breeding. The result is problems such as turbulence, blocked pipes and impaired heat transfer efficiency, as well as the time-consuming and costly business of cleaning the system.

Blocked pipes can also lead to dangerous situations, particularly with fire-fighting equipment. Problems that can be overcome by the use of CUPROBAN.

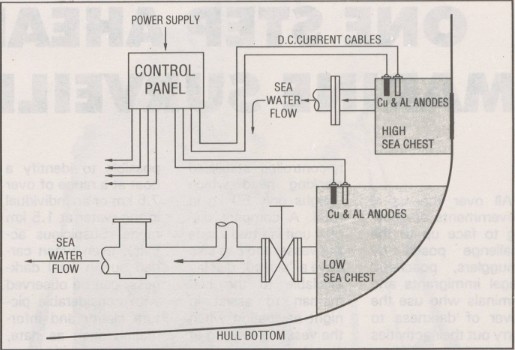

When installed, CUPROBAN electrolytically treats the seawater at the point of entry. A "floe" is produced by copper and aluminium (or soft iron) anodes in controlled amounts. This spreads throughout the system to combat fouling and corrosion. Moreover CUPROBAN is a fully automatic system with a unique feature for economically controlling and monitoring anode wear. This means a simpler and more trouble-free life for the operator.

CUPROBAN REDUCES CORROSION INHIBITS SCALE FORMATION:

* Fully Automatic Operation

* New Anode-saving device

* Safer Than Chemicals

* Simple To Operate

* Economical To Run

* Minimal Maintenance & Supervision

* Easily Fitted To Old Or New Seawater Systems

TO PROVIDE THE RIGHT CUPROBAN SYSTEM FOR YOU, WE NEED TO KNOW: 1. Number and dimensions of each sea chest and/or seawater pipelines therefrom, or pump in take/bowl diameter etc.

2. Water flow rate (each seawater service) including whether continuous, intermittent or static.

3. Supply voltage, frequency and phase input available.

4. maintenance intervals (i.e. dry-docking, cleaning of strainers, pump removal etc.)

5. Distance from AC supply to transformer/rectifier (Control Panel) and from transformer/rectifier to each anode.

For enquiry:

Jotun NOF (Singapore) PteLtd

Tel: 265 4711

Fax: 265 7484