Double-hulled Tankers - the Consequences for Jotun?

The subject under discussion is mainly two-component mastic-modified epoxy paint in light colours. However, Jotun is in a unique position since they have their own subsidiary company (Jotun Cathodic Protection) which supplies systems for cathodic protection as well as systems for rust removal by cathodic "descaling".

The ballast tanks in modern double-hulled ships comprise enormous surfaces. The most effective way to protect these is through a combination of paint and cathodic protection using offeranodes.

For older ships, whose tanks are already corroded and which are to be upgraded with new treatment, a good alternative can be to use magnesium strips. This is an efficient method of removing rust, old paintwork and other undesirable encrustations from the steel surfaces in a rapid and effective manner, provided it is done in the right way.

The combined effect of the teamwork between Jotun Marine Coatings and Jotun Cathodic Protection is considerable. It means that shipping companies as well as shipyards can use just one supplier, thus getting the best possible protection at the right price.

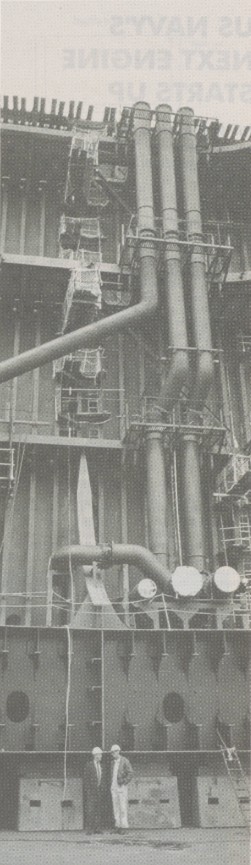

We are talking about very large surfaces - and that means significant costs - or more correctly - significant potential for reducing future costs. For a tanker of 280,000 tons dry weight, it can be a matter of 400,000 square metres of steel in the ballast tanks. The longitudinal girders alone will have a length of 60 km - or the distance of one and a half Marathons! But it is not only the size of the surfaces which is decisive. The tanks make up the "skeleton" of the ship and consist of a network of girders, bulkheads and buttressing. Difficulty of access is a big problem during preliminary treatment, application and inspection.

Although the great majority of today' shipowners are aware of their responsibilities, we cannot overlook the concept of "out of sight - out of mind". It is easy to ignore surfaces which are not visible, and to concentrate maintenance on areas with the greatest cosmetic effect - the exterior steel surfaces and superstructure.

This will certainly give charter companies, the authorities and others the impression of a well-maintained ship. However - and the majority of shipowners know this - it is corrosion damage in the ballast tanks which is crucial to the ship's safety, for the length of its life and for its longer-term maintenance costs.

It takes a lot of paint to protect the ballast tanks. If we use the ship mentioned above as an example, we will need about 300,000 litres for a satisfactory system. If the best possible paint system for this sort of surface is chosen (Balloxy HB), we are talking about a price in the order of 9- 10 million Norwegian kroner just for the paint. If we add in the costs of preparation and application we soon get up to a total of 60-70million Norwegian kroner. It might be noted here that a "cheap" solution using a thinner paint film than what is recommended might produce a saving of 2.5 to 3 million Norwegian kroner or 4 thousandths of the ship's total building costs (about USD 100 million).

The most costly solution can turn out to be the least costly if we look at the ship's overall life cycle. Statistics indicate you can reckon on extending the lifetime from an average 8-10 years to 12-15 years before it becomes necessary to make sizeable repairs to the steel surfaces. Replacing steel costs 3- 400 Norwegian kroner per square metre. In addition a stay of say, 15 days in dock can easily cost 100,000 kroner per day!

When the calculations of surveyors show that using the best paint systems available can reduce the need to replace steel to a minimum, as well as postponing it for a possible 10 years, we realise that if things are done properly, significant savings are at stake.

The changes in coatings systems that we are discussing are not in fact radically different from the traditional systems currently being used. If the dry film thickness of the paintwork is increased from 250 urn (250 thousandths of a millimetre) to 400 urn a great deal has been achieved. This means an increase in costs only for the paint. Application costs, number of coats, cleaning, scaffolding and inspection are not affected.

Unfortunately many shipping companies are still conservative in attitude, and they take time to adapt to new technology. This can easily mean they end up paying too much and too soon for repairs to corrosion damage - and this can be expensive when it means the best part of half a million square metres of steel in the ballast tanks of a single ship.

JOTUN HAS A CONSIDERABLE CHALLENGE HERE

The introduction of double hulls has presented the shipping companies with major new problems, and we have products which can help to solve these problems. The challenge is in passing on the knowledge that we have at Jotun Marine Coatings and Jotun Cathodic Protection to those who will take the final decisions in hull maintenance.