Golten in Singapore to Look After your Problems

Fuel and crew costs are an ever-increasing element of total operating expenses. At the same time, it has become widely recognized that environmental improvements and efficient aids are just as important onboard ships as in any modern industrial enterprise, and increased efficiency is a sure means of combating inflation.

Better fuel economy, increased efficiency, and comfort in the engine room are features of the production program of Atlantic Diesel A/S, Norway. It is probably the best-known company internationally for its patented system for worldwide grinding of crankshafts, now represented in Singapore by Golten Service Singapore Pte. Ltd.

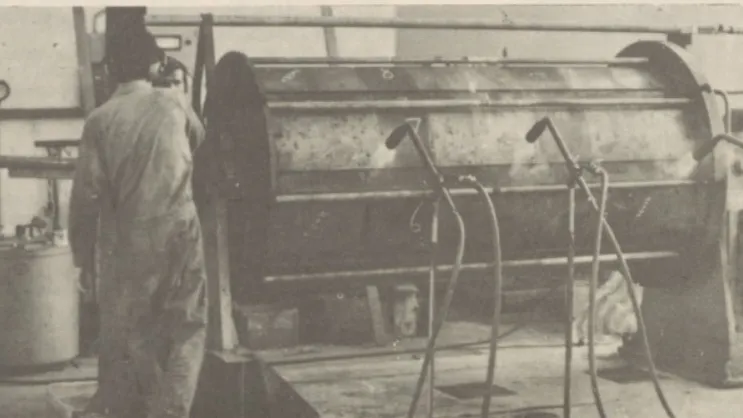

The uniqueness lies in that if any of your engines develop crankshaft trouble, there is this expertise and technology to set things right with no removal of the crankshaft at all. Main journals and crank pins on crankshafts for nearly every make of marine or industrial engine can be ground, honed, lapped, polished, and completely reconditioned in place in the engine itself — saving both time and money.

Golten Service, one of the few who offer this service, has a good availability of service engineers and portable crankshaft reconditioning equipment, and wherever required, can begin work within 24 hours. Conventional methods ordinarily take weeks to complete the process, but with the Golten method, successful completion takes only a few days.

In the near future, Golten Services intends to manufacture the GOL/SEAL stern tube seals in Singapore. These stern tube seals are activated by oil and need no springs, and they feature many advantages. Firstly, it is impossible for seawater, sand, or any other foreign matter to penetrate through the seal from outside. While oil from a gravity tank provides the pressure necessary to keep the seal closed, the oil consumption is negligible. The excessive clearance in axial or radial direction ensures perfectly even work; it is easily installed and accessible for inspection without dismantling the propeller from the shaft.

Reasonable in price and requiring a minimum of space, these seals are suitable for large, medium, and small shafts, with the additional advantage of being easily adapted to older ships.

Besides the sale of hydraulic fastening devices such as bolts and nuts, which can be fastened to the exact predetermined tension suitable for all engines, Golten Service also represents the sale of testing units designed for fuel valves in marine diesel engines.

Fuel valves are vital parts of an engine and are often subjected to impurities in the oil. The testing unit is manufactured with the purpose of eliminating this factor. It is equipped with an air-hydro pump, either together with a hand pump or separate, and has a fuel container for continuous circulation of fuel oil. There is also a distributing valve for testing one or two fuel valves at the same time. In addition, it features a lacquered testing chamber, diffused inside illumination, and a plastic window for observation.

The testing unit helps prevent damage to the vital parts of the fuel valve and will even give the engine crew a keener interest in maintaining fuel valves properly.