Marine Paints from ICI

CHOOSING THE RIGHT SYSTEM FOR THE BEST PROTECTION

For both the shipowner and the shipbuilder the choice of a good paint protection scheme is becoming increasingly important as the prices of steel and labour rise. Ships are becoming more specialised and as a consequence more costly, therefore it is important that shipowners and builders consult their paint supplier before deciding on a system.

CONVENTIONAL PAINTS

There are many types of paint to choose from; the normal types are Epoxy, Vinyl, Chlorinated Rubber and the so-called conventional. Conventional paints are modernised formulations of the marine paints that have been in existence for many years and invariably consist of primers based on bitumen together with aluminium for underwater surfaces, red lead and zinc chromates for surfaces above water. These primers consist of inorganic pigments which provide good anticorrosive properties to protect your steel.

However, a minimum of two coats and preferably three should be applied to obtain the best protection. The primers can be overcoated with antifouling underwater and gloss finishes above water.

GRIT BLASTING

Before using a Chlorinated Rubber, Epoxy or Vinyl scheme the steel should be grit blasted to Swedish Standard SA2& Immediately after blasting, a coat of Epoxy Blast Primer should be applied. The use of a wash or etch primer based on polyvinylbutyrate is not recommended for the underwater areas and for cargo tanks as they have a tendency to give poor adhesion, once the ship is in service, when used in conjunction with cathodic protection. This will cause an eventual blisting of the subsequent paint system.

CHLORINATED RUBBER PAINTS

Today there is a great tendency to use Chlorinated Rubber paints, most of which are based on “Alloprene”, a raw material produced by ICI Mond Division.

Chlorinated Rubber (CR) paints incorporate many of the good points of the conventional products, i.e. they include the use of anti-corrosive pigments, but are bonded by a resin containing chlorinated rubber, which is much tougher than the conventional type. CR paints perform extremely well in conjunction with cathodic protection, being able to withstand a greater voltage potential than conventional paints. CR products are easy to apply by normal methods (ie.

airless spray) and are normally single pack so avoiding the risk of a painter forgetting to mix the paints.

OPTIMUM PROTECTION

In order to obtain optimum protection for several years a minimum dry film thickness of 250 microns should be applied. This can be achieved with two coats of high build primer and then a thin decorative coat to suit the owner’s fleet colour.

When it comes to maintenance CR paints are ideal because they possess outstanding intercoat adhesion, ie. the bond between successive coats of paint.

CR paints dry by solvent evaporation and the solvent exerts a powerful blending and bonding action which welds the system together. This is the case even when the old coat has been exposed for years.

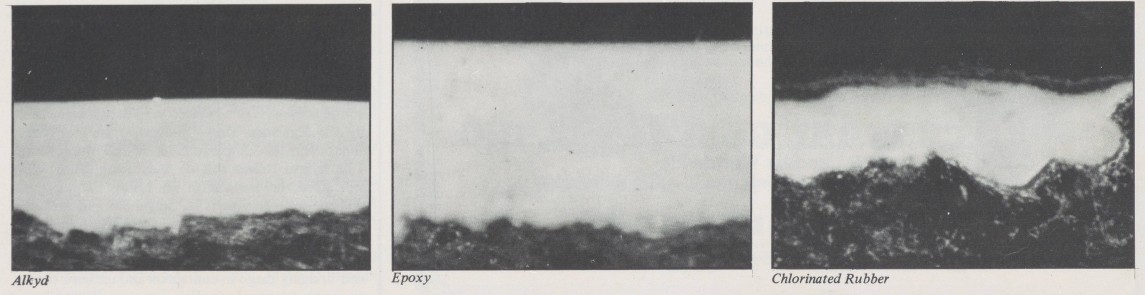

The superior incercoat adhesion of CR is clearly demonstrated by these photomicrographs. The interfaces between the two coats of Alkyd and Epoxy are clearly defined. This means that adhesion between the coats in these systems is inferior to that of CR where the blurred interface indicates a greater degree of solvent penetration and consequently better intercoat adhesion.

SOLVENT POPPING

Up to now Epoxy paints have been more popular than CR paints and the Coal Tar Epoxy type is still very popular for underwater use. However they are losing ground to CR in many parts of the world because they are extremely slow drying in cold weather conditions. Even in Singapore, contrary to common belief held by many shipyards, these paints require about 16 hours before being overcoated if “solvent popping” is to be avoided.

“Solvent popping” is caused by the use of solvents trying to escape from a tacky film which has been overcoated too soon. The solvent forces an exit through the next layer and leaves a small pin-hole for the sea water to gain access. This starts blistering eventually is the starting point of corrosion and paint failure.

ONE-COAT SYSTEMS

In order to save a shipyard labour coats, some manufacturers can offer a pure epoxy priming system which will give a dry film thickness of 250 microns in one coat. These one-coat systems are especially useful for VLCC’s and other large vessels, although they are also being used to advantage on smaller vessels when time-saving is essential.

ANTIFOULING

The choice of antifouling paint for a vessel is extremely important, and should be considered in relation to the drydock interval. There is little point, for instance, in paying for a two-year antifouling if you have to drydock annually to meet the requirements of the ship’s class. For tankers and bulkers which may do alternate voyages in ballast and load positions it is important to have an antifouling that will be re-activated on re-immersion, for example one based on CR or vinyl binders. Conventional antifoulings should normally not be applied more than 24 hours before the vessel is immersed. If they dry out the leaching process is interfered with, consequently they become less effective.

OIL RIGS

The offshore oil industry demands more sophisticated coatings, particularly ethyl zinc silicates which provide an extremely tough and durable coating when left exposed. If even greater protection is required they can be overcoated with any of the high performance systems mentioned above. Under normal circumstances it is advisable to apply a thin tie coat between the zinc silicate and the thick coating. This type of system is often used in the “splash zone” of rigs where corrosion can be particularly severe.

This article is by no means intended to be a comprehensive survey of the types of marine paints and painting systems available.

For more technical information, the reader is invited to contact: Mike Gark, ICI Paints (S) Pte Ltd., Telephone: 650677