Neutra Rust - an Environmental Alternative to Rust Prevention

For many years marine coatings have been associated with highly toxic products. Indeed, many users hold to the myth that if there is no pain, there is no cure. However, today rust prevention does not necessarily mean damaging the environment.

With the current harsh economic climate shipowners are more reluctant to renew their fleet, hence there is a great demand for maintenance products. There has been an increasing interest in alternative products as environmental pressure groups have become more influential on legislation, but as these have often failed to satisfy the same performance requirements as their more toxic brothers, ship-owners have been reluctant to use them.

However, this attitude will soon be a thing of the past, as new legislation and rising standards are focusing more on the greener aspects of business.

THE PROBLEM

All ferrous metals corrode unless protected. The process is a complex chemical action which always involves the availability of moisture and oxygen. This persistent, destructive and degenerative process is accelerated by associated surface contaminants such as mineral salts and acids. Only by absorbing or neutralising surface pollutants and completely excluding moisture and oxygen from the metal surface can an adequate long-term protective system be achieved.

Existing rust control processes are only partially successful because they do not adequately cope with all three basic causes of ferrous metal corrosion:

* the elimination of surface contaminants;

* the removal of free moisture and oxygen from metal surfaces and

* the protection of the treated surface by an impenetrable membrane.

THE SOLUTION NEUTRA RUST has developed a range of products which recognise the new needs and trend for more environmental products. This range is also highly successful at attacking the above three factors. The products are non-toxic and do not contain phosphoric acid or lead.

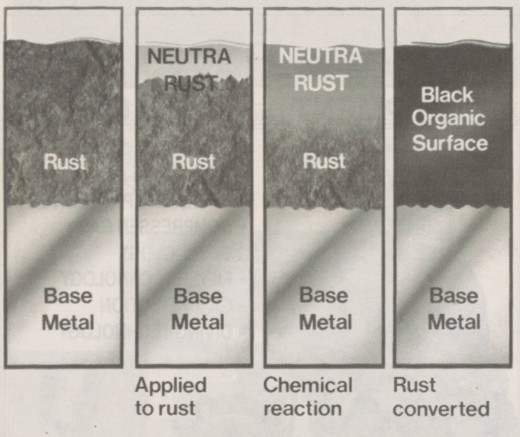

NEUTRA RUST 661 RUST CONVERTER is converted on contact with the rusted surface to a black, complex organic iron compound by a deoxygenating agent incorporated in the emulsion. During the reduction reaction the corrosion resistant layer is formed by utilising all the surface moisture and oxygen. This layer then dries to form an impermeable barrier to oxygen and moisture. NR 661 dries on rusted surfaces and chemically converts these to a black non-tacky layer in 30 minutes under normal conditions.

There has been an increasing demand for products that do not require the extensive surface preparation that many traditional coatings need in order to work effectively. Also, many shipowners find that for smaller rust prevention jobs it is easier to deal with a product that needs little surface preparation.

When using NEUTRA RUST 661, the area to be treated is simply hydrojetted in order to remove any grease and wire brushed if necessary to remove loose particles and dust. NR 661 can then be applied to the area by brush or spray. Complete inhibition and protection is achieved immediately and the black protective compound formed on the rusty surface does not require washing or pacifying.

The product has a proven track record in the marine environment. Indeed, a salt spray test conducted at the Research and Productivity Council in Canada found that NEUTRA RUST 661 protected the steel panels from the highly corrosive salt fog environment (as specified in ASTM B117-85, appendix A) for 1000 hours. Corrosion damage was minimal to nonexistent on the coated panels, even along the scribe lines.

THE SYSTEM

The continuous chemical curing of NEUTRA RUST forms a chemical bond with every metal interface, pacifying, neutralising and chemically converting rust. The black chemical compound layer is completely neutral and can be used as a primer, without further treatment, for standard or synthetic resin lacquers, oil-based paints, two component lacquers or bitumastic and oil tar-based finishes including micaceous iron-oxide paints.

NEUTRA RUST has developed its own top cost which, combined with the NR 661, provides a good system for the end user. NEUTRA RUST TL is impervious to water and oxygen and helps to prevent any future corrosion. Like the rust converter, NR TL is water based and environmentally friendly. The product is non-flammable, non-toxic and non-hazardous. However, effectiveness has not been compromised; the coating has shown strength and flexibility and has proven to be applicable under most circumstances.

Environmentally friendly products do not necessarily mean an increase in expenses or a compromise on effectiveness. Today, most paint manufacturers produce coatings which replace the more dangerous products and NEUTRA RUST claims to have developed a system which has all the qualities of a traditional coating.