New Diesel Engines for Bulk Carriers and Tankers

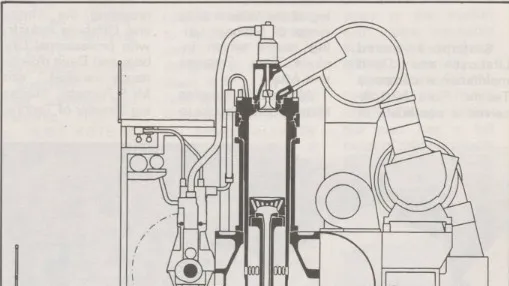

New Sulzer Diesel Ltd of Winterthur, Switzerland, has added two new engine types to the sulzer RTA series of low-speed marine diesel engines. The Sulzer RTA48T and RTA58T engines are specifically designed for the propulsion of bulk carriers and tankers.

With cylinder bores of 480 and 580 mm, these engines have maximum continuous outputs of 1850 and 2720 bhp/cylinder (1360 and 2000 kW- /cylinder) at 124 and 103 rev/min respectively. Thus, in models with five to eight cylinders, they together cover an overall power range of 5600-21 760bhp(4100-16 000kW).

Their parameters were selected after thorough market research and technical evaluation to give the best match to the power and speed requirements of bulk carriers and tankers in the approximate range of 25 000 to 85 000 tdw.

The engine ratings are within the scope of experience, with brake mean effective pressures (BMEP) of about 18.2 bar, while the mean piston speed is 8.3 m/s. In effect, the piston strokes were selected to obtain, with this piston speed appropriate propeller shaft speeds for the envisaged ship types. The cylinder bores were, in turn, determined by the power outputs required by these ships. The result is that RTA48T and RTA58T engines will be capable of optimally matching ship power and speed requirements.

The new designs are notable for their compact dimensions. The engines have clear advantages in length. They will thus give ship designers more freedom in creating very short engine rooms. This will be aided by the provision for a degree of flexibility in the fore and aft location of the turbocharger and scavenge air cooler module for best engine room arrangements.

Particular care has been taken in the design of the RTA48T and RTA58T engines to obtain reliable long times between overhauls. Their designs are based on the RTA-2U engines which were introduced in 1992, and will thus benefit from the considerable improvements in reliability achieved during the long development of RTA-series engines. The design objective is a time between over hauls of the principal components of 15.000 hours.

Notable among these is the excellent piston running behaviour given by the combination of multi-level cylinder lubrication, appropriate material properties in the piston rings and cylinder liners, the optimum temperature levels and distributions, and the highly efficient water separators after the scavenge air coolers. In this respect, the cooling bore geometry in the cylinder liners has been further adapted to obtain optimum temperatures while having low thermal strains and low mechanical stresses.

The high level of the camshaft allows shorter high-pressure pipes from the valve-controlled fuel injection pump and thus even better fuel injection regulation in spite of the elongated stroke.

Both engines will be able to meet the IMO limits for NOx exhaust emissions that come into effect in 1997 without any additional equipment. The NOx levels are reduced simply by adapting the engine tuning. This is facilitated by the electronic VIT (variable-injection timing) system now standard on Sulzer RTA-series engines which affords a particularly-high degree of control flexibility.

The sturdy engine structure with its low stresses and high rigidity has been adapted for easier fabrication. Furthermore, the engine designs have been optimised throughout to reduce manufacturing costs. Engine components have been simplified and reduced in size and weight.

Another low-cost option has been intro