NKK Develops Automatic Crane Control System

NKK Corporation of Japan announced that it has developed a highly accurate crane anti-swing and positioning control system that employs an optical-fibre gyro sensor, now in use at the company's Keihin Works.

The system was developed to enable accurate automation of both newly-installed and existing crane operations at minimal expense. It allows existing ceiling cranes to be automated without modification to the main unit.

The advantages of the new system are:

* it allows highly accurate anti-swing and positioning control of cranes, made possible with a full-time swing angle feedback control device that incorporates a swing angle sensor based on an optical-fibre gyro sensor;

* it minimises mechanical remodelling of the crane by applying shockless speed control and anti-yawing control when the crane is switched on and turned off;

* it achieves low cost with the general-use sequencers and package software.

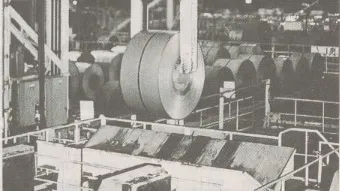

NKK's Keihin Works is using the new control system on coil shipping and receiving cranes at its hot and cold-strip mills and plate mill's finishing yard. "We realise that with a high-accuracy crane that offers positioning with a j^mm error range, there is no need for crane operators, as previously required," said Mr T Goda, general manager of NKK Singapore Representative office.

"By simply changing a portion of the software, this new control system can be adapted for a wide variety of ceiling-mounted cranes in the steelworks and other plants and facilities," Mr Goda added.

NKK is marketing the control system under the brand, NK Shockless Crane System, through its wholly owned subsidiary, Kokan Densetsu Kogyo KK. A standard model costs 50 million yen, and Mr Goda said NKK hopes to achieve annual sales of one billion yen in the first year.

NKK Corporation, Japan's second largest steelmaker, is a diversified company specialising in steelmaking, heavy industries, shipbuilding, advanced materials and urban development, electronics and biotechnology.