Surface Preparation by Hydrojetting - an Acceptable Alternative

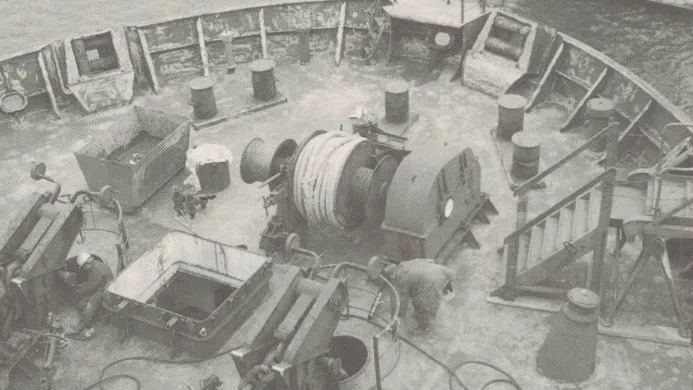

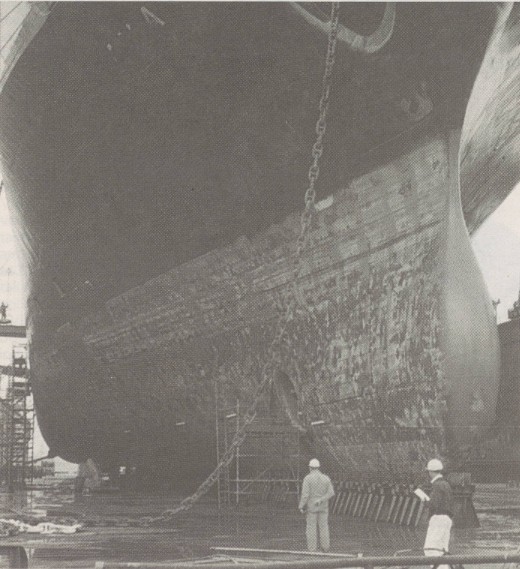

Increasingly, ultra-high pressure hydrojetting is the alternative to blast leaning. There are two primary reasons for this development. For environmental reasons gritblasting is no longer available at an increasing number of drydocks, particularly those close to built-up areas.

Secondly, when a vessel is aging or when freight rates are poor, a shipowner may decide against the initial cost of blast cleaning before recoating, in spite of the long term economic benefits.

Hydrojetting is relatively quick and low in cost and does not generate the grit or dust which pollutes the atmosphere.

Equipment has improved dramatically in recent years and very acceptable standards of surface preparation can now be achieved.

No single set of preparation standards has been adopted by the industry and ISO 'SA' standards can only be achieved by blast cleaning.

Published guidelines include the German STG2222 and the NACE/SSPC (USA). These do not differ significantly and can be summarised as : High Pressure Water Jetting 680-1,700 bar/10,000-25,000 psi (68-170 MPa) Ultra High Pressure Water Jetting-above 1,700 bar/25,000 psi

Whilst hydrojetting will not achieve the long-term corrosion protection offered by blast cleaning to Sa 2.5 followed by application of a pure epoxy or chlorinated rubber coating, it can substantially delay the onset of corrosion by use of a surface tolerant treatment.

Jotun has closely monitored the development of hydrojetting and provides a range of products compatible with the special needs of such prepared surfaces.

They provide tough protection at modest cost and offer specific benefits for particular vessel areas.

For enquiry :

Jotun NOF (S'pore) Pte Ltd

Tel: 265 4711

Fax: 265 7484