Watertight-integrity Testing Is Quick, Easy and Clean

Watertight-integrity testing can be carried out quickly, easily and cleanly by means of a portable ultrasonic system developed by a British company.

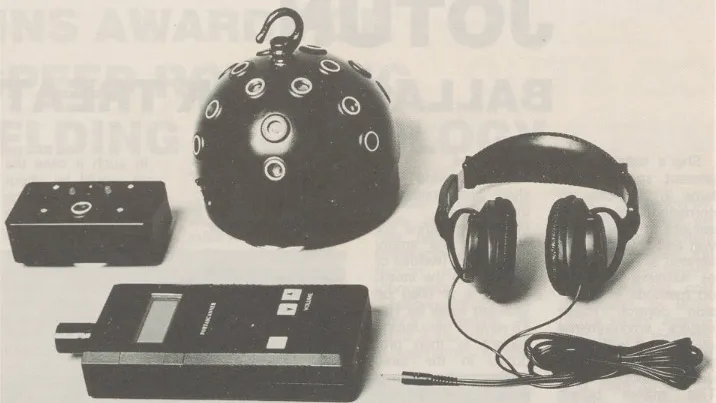

One person can perform tests using the system 's handheld 190x100x40mm receiver and headphones to detect ultrasonic signals transmitted by a generator placed behind the element being tested. Ultrasonic signals penetrate damaged seals but not solid bulkheads or seals with watertight integrity, and any 'leaking' signals are indicated on the receiver's digital liquid-crystal display and by oscillating sound on the headphones. Leak sites can then be marked for repair.

Ultrasonic signals are transmitted by a standard unidirectional generator, measuring 100x50x50mm and filling a volume of approximately 15,000m3, or an omnidirectional hemispherical bulk generator with a diameter of 200mm, height of 120mm and filling 43,000m3. Both generators can be held in place by rugged 'clamp-on' limpet magnets, and the bulk generator can be suspended by a fixed hook.

No preparation of the test area is required, and there is no need for spaces to be closed for tests to be carried out. For example, parts of a ship's hatch cover can be tested without totally shutting the hold, and the test can be carried out with spaces empty or full or when they are being loaded, unloaded or repaired. Since the system's high-frequency tones cannot be mistaken for other sounds, it is suitable for use in noisy environments.

No special training is needed, and familiarisation with the unit can take just five minutes. In addition to marine applications, the system can also has uses in the aviation, industrial, petrochemical, transport and offshore sectors.