Extensive Damage Reconstruction on LPG Tanker - Mundogas Energy

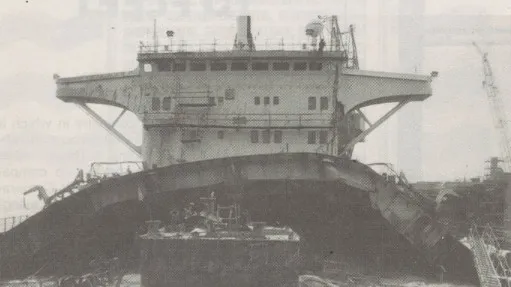

Sembawang Shipyard has, over the years developed its expertise in the refits of Liquid Petroleum Gas (LPG) and Liquid Natural Gas (LNG) vessels. This capability was successfully demonstrated on the LPG tanker, MUNDOGAS ENERGY (ex-Nyhammer). The vessel sustained substantial damage due to an explosion onboard during repairs in South Korea in November 1993. Built in 1975 by Chantiers Navals De La Ciotat (France), Nyhammer was bought by Macarthur Company Ltd, Hong Kong. The vessel has been renamed MUNDOGAS ENERGY and is managed by Arbross Shipmanagement Co Ltd of Hong Kong, a major operator of LPG tankers and a regular customer of Sembawang Shipyard. The challenging task of reconstructing the damaged areas was entrusted to Sembawang Shipyard while the vessel was re-classed with Lloyd's Register, which surveyed the repair requirements.

MUNDOGAS ENERGY arrived in the Shipyard on 1 st August 1994 to commence five-and-a-half months of extensive damage reconstruction work and special survey. Detailed pr-docking planning and preparatory work were carried out by the dedicated project team, headed by the shiprepair manager. Upon arrival, further thorough onsite inspections were carried out to determine the full extent of the damage prior to commencement of initial work processes such as cleaning, marking and cutting.

Extensive dismantling and removal work were carried out prior to repairs and renewal of various systems, for example, the removal of the main deck catwalk, cable trunking and all cargo and hydraulic piping prior to cutting away the damaged plating. Additionally, all main deck electrical cabling was disconnected from the engine room main switchboard area and was pulled back to No 3 dome. All damaged polytubing for the cargo valve control systems was removed. To avoid unnecessary renewal and replacement work for cost efficiency, careful planning during the dismantling and renewal phase was essential.

The following renewal and replacement work were carried out:

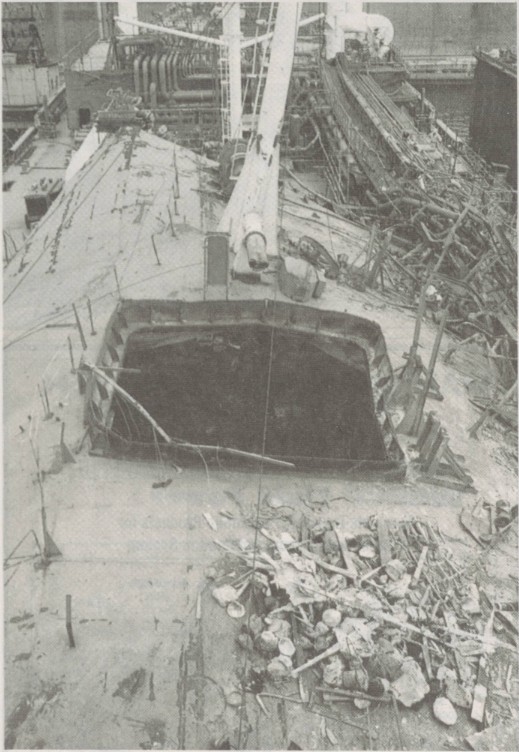

DAMAGED TANK RENEWAL

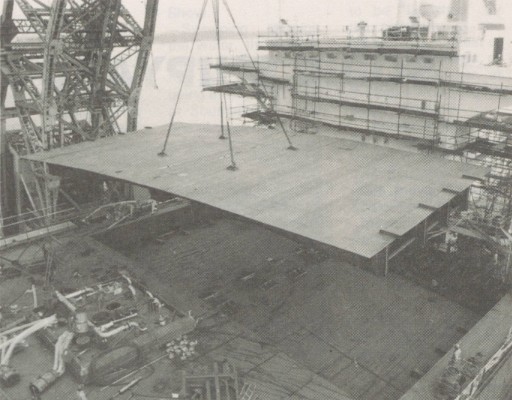

As the result of the explosion, major reconstruction of the damaged tank required extensive steelwork renewal in way of No. 4 cargo tank totalling some 800 tonnes. This involved the complete replacement of the damaged plating from port to starboard shipside main deck (3 sections each 100 tons), dome deck (4 sections each 60 tons), complete dome (4 sections each 65 tons), a new dome hatch was fabricated separately together with rubber expansion bellows, for cargo tank and hull internals, NV4-4 low temperature steel was used in order to meet stringent Classification requirements.

The forward, aft, port and starboard bulk-heads in the damaged tank also required to be cropped and renewed. Additionally, the support structures, including strake plate, top stringer, stiffeners, web frames and swash bulkheads were renewed. All anti-pitching, rolling chocks and supports on the tanktop were replaced to their original position. To conform to Class welding procedures, all weld seams were X-rayed. On completion of repairs, the cargo tank was satisfactorily pressure tested.

PIPING RENEWAL

All pipelines in way of the damaged No.4 cargo tank/main deck area, including cargo lines, inert gas main, fire main, deck service air lines, instrumentation lines, bunker lines, etc., were renewed in their entirety. All welds were subjected to 100% X-ray testing.

CARGO TANK REINSULATION

The No.4 cargo tank insulation was restored to its original condition, the tank dome was re-insulated with polyurethane, the top of the cargo tank with a 200mm thick rockwool blanket and the entire void space filled with Perlite; efficient insulation being of paramount importance in maintaining the low temperature conditions necessary for the refrigerated carriage of LPG.

RECABLING WORK

All electric cabling and electrical equipment were checked to ensure satisfactory condition as substantial cable renewals had been effected by Shipyard staff in way of the damage areas.

AUTOMATION SYSTEM

All cargo control automation system piping was renewed in stainless steel.

REINSTALLATION OF PUMPS AND CARGO VALVES

A damaged deepwell pump was removed for repairs and renewals. New pump seating was fabricated and installed between come and tanktop. Laser sighting and alignment were carried out for installing the pump foundation.

In addition, submersible pump trunking was partly renewed and the height was adjusted before the welding was carried out. The damaged cargo valves were removed and renewed.

NEW INSTALLATION

Additionally, booster pump with cargo heater, piping and valves and new starter panel cabling were installed.

SPECIAL SURVEY

Concurrent with the damage repairs in way of No.4 cargo tank, special Survey-Hull and Special Survey Liquified Gas Tankers were completed to Class satisfaction. As part of the requirements particular attention was paid to Nos. 1, 2 & 3 cargo tank domes, all insulation, valves and pipework having been removed, the area grit blasted to allow dye penetrant check of all cargo tank penetrations with renewals, complete with X-rays on all welds, being completed as deemed necessary. After satisfactory pressure testing of cargo tanks, cargo tank domes were restored to original condition and re-insulated. All cargo tanks were staged throughout to facilitate high pressure water wash, a major staging exercise that demonstrated Sembawang Shipyard's skill in this area.

OVERHAUL OF MACHINERY

Windlasses, mooring winches, cargo pumps and valves actuators were sent to the machine shop for overhauling and testing. Careful examination was carried out in the machine shop to ensure the effective operations of all machinery.

The tailshaft was withdrawn for survey and DB ballast system valves completely overhauled and tested as well while the vessel was being dry docked.

HULL CLEANING, BLASTING AND PAINTING

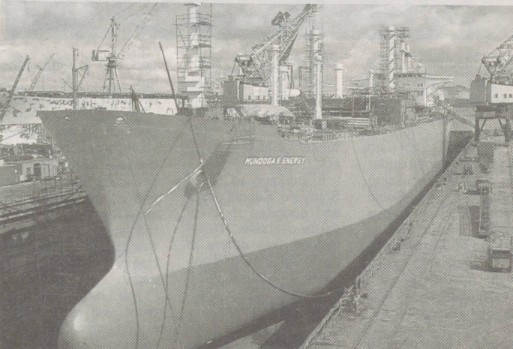

While* MUNDOGAS ENERGY was in the drydock, the entire hull was washed down with fresh water to remove all contaminated particles, debris and damaged paint. Gritblasting was carried out by the yard to meet the SA2.5 standard requirement and three coats of paints including primer were applied to the external hull in accordance with owners' specification. The superstructure including funnel was gritblasted and coated and finally the logo of her owners proudly installed onto the funnel.

All in all, extensive work was carried out round-the-clock and all work was successfully completed within 166 days including 10 days in drydock. MUNDOGAS ENERGY set sail from Sembawang Shipyard on 14th January 1995 for its first commercial charter under the new owners.