NKK Commissions Integrated Transport System for Bars/sections

NKK Corporation of Japan has commissioned a new integrated system for transporting bars and sections between its Fukuyama Works and transit bases, the move came amid rising distribution costs and shipping labour shortages which have forced Japan's steelmakers to improve steel product distribution efficiency.

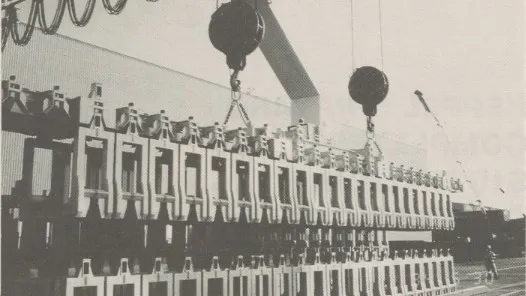

The latest system for bars and sections is the second of NKK's distribution streamline efforts. Employing specially developed ll- frame racks, it enables highly efficient unit-based cargo loading/unloading, storage and transportation, providing a significant reduction in manpower, improved worker safety and lower distribution costs compared with conventional systems.

In efforts to alleviate transportation problems, NKK first developed an integrated coil transport system using specially-designed RORO (roll-on roll off) ships. These went into service in 1991.

Conventional methods of transporting bars and sections are labour intensive and incur high distribution costs. Due to their different lengths (5-25m) and uneven shapes, bars and sections including rails sheet piles and H-section, are difficult to transport in units. NKK's system reduces the amount of labour needed by using unique separable U-rack containers and automated twist-lock handling units for the racks. The system also incorporates specially designed holding equipment for use aboard ships to prevent the cargo from shifting and to allow easy collection of empty racks.

The new system's most distinctive feature is improved work efficiency in unit handling. It does not require manned slinging work, which saves considerable labour and time. In addition, work safety is significantly improved. "Using the. system, the ship's productivity between the Fukuyama Works and the transit base at Shiohama has almost doubled," said Mr T Goda, general manager of NKK Singapore representative office.

Of further advantage, the system requires minimal investment in equipment, as it can use existing cranes, warehouses and ships after minor conversion work. Total capital spending for the new system was about Yen 2.3 billion, equivalent to the cost of one RORO ship.

The new system is currently operating between NKK's Fukuyama Works and transit bases at Sakai and Shiohama, carrying 15,000 to 17,000 tonnes per month. NKK plans to extend the service to include Nagoya and Yokohama next year. It hopes to play a key role in supporting Japan's steel industry achieve higher distribution efficiency, which has traditionally faced problems with integrating the transport of longer-gauge steel products, Mr Goda added.

At the same time, NKK intends to invite other domestic steelmakers to jointly operate the new transport system to further improve the productivity of coastal shipping and steel product distribution.

NKK Corporation, Japan's second largest steelmaker, is a diversified company specialising in steelmaking, heavy industries, shipbuilding, advanced materials and urban development, electronics and biotechnology.