Technology and Welding Equipment for Shipbuilding Industry

ESAB — the large Swedish welding and gas cutting company is represented in Singapore by a subsidiary, ESAB Singapore Private Limited, which was established 1974.

Today, ESAB (S) Pte. Ltd has its own premises in Jurong, with Sales and Administration Officers, a Warehouse for stock keeping large quantities of welding consumables, machines and spare parts.

Further, there is a repair/service shop, a demonstration/ training shop and a lecture room. In the Showroom, a wide range of equipment is on permanent display.

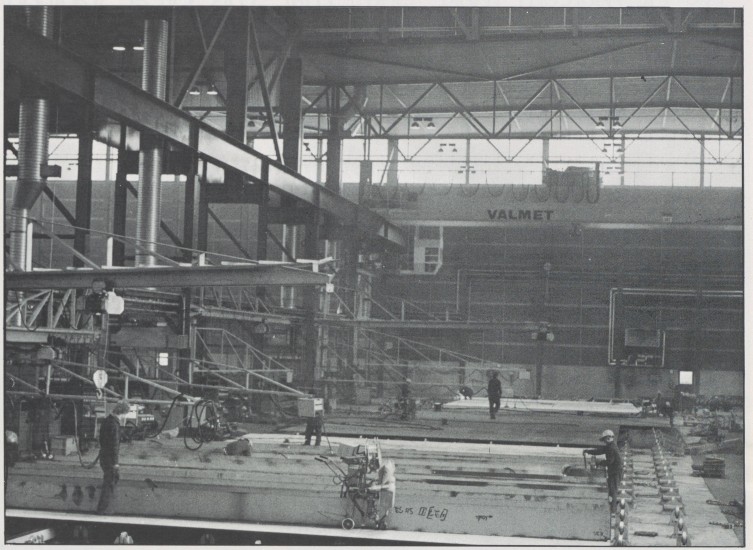

In the background, ESAB A9 semi-automatics are used for tack-welding plates. In the centre, ESAB A6 T submerged arc welding tractors for butt welding first and second side. In the foreground, ESAB A9 are used for tack-welding the stiffeners before submerged arc welding with ESAB A6 DK takes place. The handling equipment including rollers, chain conveyors, tack-welding station, turnover stops, etc., are all supplied by ESAB.

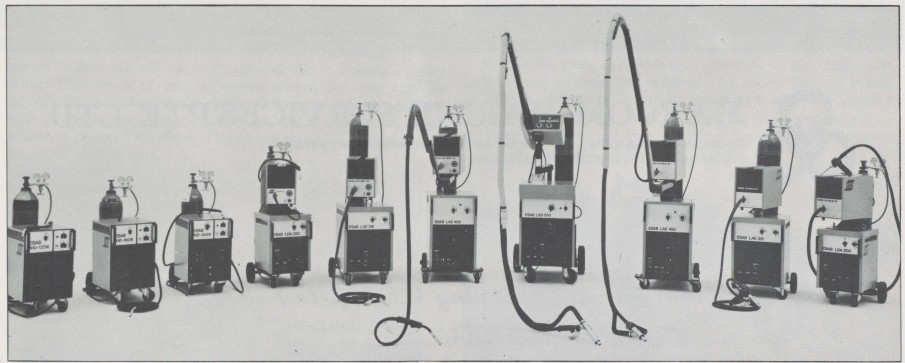

Semi-automatic Welding Machines

The ESAB range of Semi-automatics going from 125 Amp at 40% dutycycle — A10 125K — to 600 Amps at 100% dutycycle — A10 600 (not shown on this photo)

—, is the widest being offered in the world today. It includes compact — single knob control machines (A 10 125/160/250K), separate wire feed unit types with wire push feed (A 10 200/315/400/500/600) and push-pull wire feed types for welding of aluminium and where long welding hoses are required — up to 16 m (A9 200/315/400). The machines are built up of a component system which mean that feed units, hoses and guns are interchangeable within very wide limits. The photo shows three types equipped with counter balance for the welding hose. A device which reduces the weight of the gun — simplifies the work for the welder, takes the hose off the workshop floor — better utilization of the floor plus reduced risk of damage to the hose, and which gives the welding hose a very smooth bend, which in turn gives a good wire feed.