Detecting Fumigation compounds in Cargo transport units

The Maritime Safety Committee of IMO, at its 87th session on 14–21 May 2010, approved a number of circulars which provide guidance to improve the safety and efficiency of shipboard operations. One of these topics was the recommendation that addresses the hazards to personnel arising from the operations involved in the carriage of fumigated cargo transport units and will apply to all personnel involved on or after 1 January 2011.

Key to addressing these hazards is that before entering the cargo transport units, all personnel should assess the risk as to whether it is safe to enter and to determine the presence of fumigant by the use of gas detection equipment. To ensure that the right gas detection equipment is used, the knowledge of what fumigant is used for fumigating is of paramount importance to selecting the right type of equipment for a proper assessment.

Here in this article, we would like to address the most frequently asked question: "Is there one device to measure all these fumigation compounds?"

Over all these years, we learnt from our experiences that a combination of direct-reading detector tubes and portable electronic instruments has proven to be the solution for fast and reliable detection and measurement of both toxic industrial chemicals and fumigation compounds. With the direct-reading tubes, the instruction for use of each tube will guide the user to properly evaluate the different colour stains in the detector tubes and the comprehensive information in the display of a portable instrument gives a clear picture about the kind of chemicals being present and their concentrations, in conjunction with audible and visual alarms to warn the user if the alarm thresholds are exceeded.

Here's our recommended strategic approach:

a) If the fumigants used are known, this will simplify the selection process and will better prepare the gas tester with the right detection equipment and protection equipment that will be needed to protect him/her.

b) If the fumigants used are unknown, additional measures must be put in place to ensure that the risks are reduced to the lowest.

c) In addition to the selection of the type of measurement instruments, where ease of use and long calibration interval are preferred, training on how to use these instruments is extremely crucial.

1) The Colorimetric Tubes Approach

Direct-reading detector tubes have the big advantage of allowing the measurement of a large variety of different chemicals. Based on the length-of-stain, the discolouration of the reactive chemicals inside the tubes is a measure of the substance concentration. With the printed-on full scale marking in units such as parts per million (ppm), the concentration can be evaluated directly on site where the measurement is taken. Since these are pre-calibrated during the production process, no calibration is required by the user.

To take a measurement, ambient air is drawn through an opened tube by means of a manually operated bellows pump — no battery is necessary. With proper storage conditions for the tubes prior to use, a quick check on the pump for leaks and the expiry date for the tubes, the system is ready whenever the user needs to perform a measurement.

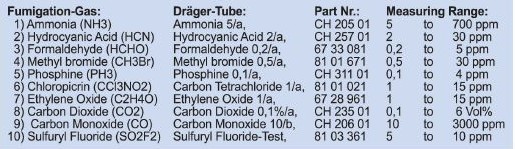

If the substances are known, the following tubes can be used. If the substances are unknown, the Dräger SimultanTest Fumigation for the following gases: NH₃, HCN, HCHO, CH₃Cl, PH₃, with one scale mark at the TLV, can be used. With this test kit, the measurement time is reduced by the factor of five, because five test results can be obtained in 3 minutes. If there is no indication with the SimultanTest, perform further single measurements with the following Dräger tubes. The sequence of the measurements is flexible. Tubes for other fumigation compounds are available on request.

2) The Portable Instrument Approach

These devices use proven sensor technologies such as Electrochemical Sensor, Infrared Sensor, and Catalytic Sensor for the continuous monitoring of oxygen, combustibles and flammables, and other toxic gases commonly found in many workplaces. The known compounds (e.g., Phosphine) can be measured with the appropriate sensors for use with the portable instrument. This should always be the first choice over the direct-reading detector tubes due to the continuous measurement mode with display and alarm warnings.

Over the years, these instruments’ performances are continuously enhanced to help gas testers with functions such as leak detection, confined space clearance measurement, fleet management station with automated bump test and calibration features for instruments that can detect either one gas or more gases (up to 7 gases), which are becoming the industry norm.

In addition to the standard gases, most of these instruments can also be equipped with a Photo Ionization Detector (PID) sensor as a screener for VOCs, or they can be used to detect Benzene specifically with a pre-tube. This is especially crucial if there is a large number of volatile organic compounds (VOCs) that are not just flammable but are also toxic. One of the drawbacks for this sensor is that, like the catalytic sensors, the working principle of photo ionization detectors (PID) cannot be substance specific.

With more stringent risk assessment and management requirements and the reduction of TLV limits for the protection of workers' safety and health in many countries anticipated, the need for more selective, sensitive, and accurate direct-indicating measuring instruments will continue to be a key success factor in Health and Safety Management Programs for workers.

Understanding the pros and cons of each instrument selected for these compounds with their respective working principle is already half the battle won. This is one of the many reasons why a single solution strategic approach for a safer workplace will no longer be sufficient. But the good news is that we can and should always find the right combination with all the various different technologies for a cost-effective and efficient solution.

This article was originally published on Marine & Industrial Report newspaper Vol 42 No.3 Issue last June 30, 2020.