One tough Tug

The Nordic is one of the most powerful, most advanced emergency towing vessels (ETV) in the world- and it even has been approved for deployment where toxic or explosive materials have been released.

It's cold outside. And stormy. The waves in Hamburg Port have small vessels wobbling like prizefighters on the ropes. But the crew of the ETV doesn't recognize much of it. In the engine room, between two gas-protected MTU engines rated at 11,500 horsepower each, the temperatures are tropical. At least, the only thing that distinguishes the 78-meter-long Nordic from other tugboats is its size.

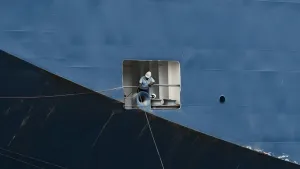

From the outside, it becomes clear that the Nordic is something extraordinary. Dräger developed technical equipment that makes it a unique tug: a protective citadel allows the crew to work in a self-contained area under hazardous atmospheric conditions, such as when a damaged ship is burning and toxic gases are released.

In the winch room, there are two huge drums. Wrapped around the winches are steel cables 1.2 kilometers long and as thick as a man's leg. By now, it’s becoming clear why the ship is unlike any other vessel. This system has a bollard pull of approximately 200 tons. That's enough power to hold even a supertanker in a storm and prevent it from stranding on the coast. The Nordic was designed for just this sort of maritime disaster, and its mission, chartered by the German government, is to keep the waters of the North Sea safe.

New Safety Concept

The vessel was built by the Arbeitsgemeinschaft (ARGE) Coastal Protection, a group comprising the towing and salvage companies Bugsier, Fairplay Towage, URAG Unterweser Reederel, and Wiking Helikopter Service GmbH. Nordic is the world's first rescue tug designed to operate in hazardous conditions.

The vessel has ten years of planning, two years of construction, and two months of testing behind it. Since January 2011, the special-purpose tug has been patrolling in gale-force winds close to the shipping fairways off the East Frisian coast. It was a maritime accident that first compelled the German government to launch the "Maritime Emergency" project. The case of the freighter Pallas, which ran aground in October 1998, was the basis for a report by an independent commission of experts, and their findings in turn marked the conception of Nordic.

Pallas ran aground off the island of Amrum, and the 90 tons of oil that spilled in the process polluted a nearby bird sanctuary. As a result of this and other damage, the new safety system stipulates that ETV must be ready for deployment at any time. The "seagoing fire brigade" that was created comprises 16 men who live and work on the Nordic. If a damaged ship is drifting toward the German coast, the emergency towing vessel can reach it within two hours.

Versatility

The great versatility of the Nordic is what makes it especially useful for emergency deployments. Commenting on the structural profile, Chief Engineer Robert Nüss said, "We had to find a good compromise; we needed to reconcile many requirements." On the one hand, the tugboat has to be prepared for storms on the open seas. But its draft can't exceed six meters, in order to operate in the North Sea's shallow tidal waters. And when it comes to speed, the brawny propulsion system can move the Nordic at 20 knots (about 37 kilometers per hour), a brisk pace for quickly reaching damaged ships.

The most important thing, however, is that the Nordic is the first emergency towing vessel in the world that can operate in a hazardous atmosphere where other tugs would have to abort their missions right away. Given the increasing prevalence of hazardous materials in the cargo holds of ships, the demands are increasing all the time. In close cooperation with Dräger, the engineers came up with a design that ensures the tug is supplied with safe air in self-contained areas that are shut off from the atmospheric conditions outside.

In the event of deployment, airlocks on the main deck and the "A" deck can be used to exit the citadel, which is in turn divided into two areas with different air pressures: Area A, which is permanently used by the crew, and Area B, where crew members don't generally stay. During a mission, an overpressure is maintained throughout the whole ship. The supply of clean air for the overpressure areas makes it possible for the ship to operate for at least eight hours in this mode, and this can be extended when necessary with the purge air reserves.

Jens Münzer, First Mate on board, explains the effect of Nordic's high-tech equipment: "The crew can seal itself off completely from the outside world and start to rescue and stabilize a damaged ship." This is an advantage that can prevent disaster during an emergency.

Red Alert

When designing the protected area, the engineers faced formidable challenges. The measures that are relied on to guarantee the protected space are unlike the NBC protection used in the military: With NBC, toxic substances can't be kept out by means of appropriate filters. If a ship is damaged, there may be a mixture of toxic or combustible products against which the usual NBC filters with activated charcoal can't provide full protection. There's simply too much that remains unknown about the conditions in which a crew will have to be deployed. That's why there had to be an onboard supply of clean air independent from the external atmosphere.

Since crew members need to enter and leave the locked-down citadel during a mission, and the gas locks required for this have to be purged with clean air, the new ETV is equipped with a large supply of safe air. It carries nine modules, each consisting of twelve 50-liter bottles of compressed air. If a towing connection is needed while the tugboat is locked down for protection against hazardous gases, three crew members leave the citadel and enter a changing room where there is an overpressure. Two crew members stand by for them as a rescue team. Only after the first three crewmen have put on their Dräger Chemical Protective Suits (CPS) 7900 do they leave the changing room and enter the winch-house on deck. Air-curtain units are installed at the entrances to the gas lock and winch-house to reduce any flow of contaminants into areas beyond them. Such air-curtain units are often found on land in department stores, where they act as barriers to cold air during the winter months. Dräger uses them in tunnel rescue trains to keep contaminants away from firefighting and rescue teams and to allow the teams to get to work without the protracted efforts of moving through airlocks.

A fan on one side blows the ambient air past the door opening and into an intake vent on the opposite side, where it is guided back to the fan in a cycle. The air is circulated back to the fan duct located above the entrance door. "Thanks to the experience Dräger has gained with rescue trains, we know that air-curtain units minimize the influx of contaminants over a period of hours," says Chief Engineer Nüss.

Cleverly Devised System

The decontamination of the crew after a mission is also clearly regulated. In the winch-house, there are several shower stations right next to the gas-lock entrance. Contaminated personnel clean their CPS first and then enter the gas lock, where they undergo another cleaning process. To this end, multiple high-pressure nozzles have been installed in the ceiling and walls. These remove contaminants from the CPS and use the atomized spray to "scrub" gaseous pollutants out of the gas-lock air. After this in-depth decontamination, the gas lock is finally purged with clean air in order to flush out any leftover contaminants. Only then does the crew reach the door to the changing room. If crew members haven't been sufficiently decontaminated, they remain in quarantine with their CPS on in the changing room and disembark at the nearest port.

Another gas lock on the A deck serves as an entrance to the treatment room, which is outside of the citadel and functions as an additional quarantine area. With the supply of air that's carried inside the CPS, crewmen can breathe in it for a maximum of 30 minutes. In order to stay longer, they can draw breathable air from several connections, e.g. in the changing room, in the treatment room, inside and in front of the gas locks, in the winch room, and behind and inside the deckhouse. These connections are linked to an onboard supply of clean air. The PAS ASV switch unit developed by Dräger automatically switches between external air supply and compressed air respirator when necessary. This makes it possible to maximize the period in which breathable air is available when crewmen are putting on or taking off the CPS, entering or exiting airlocks, or undergoing decontamination. This control unit has the major advantage of being almost completely mechanical in design; it operates with practically no electric or electronic components.

For 28 consecutive days, the Nordic patrols the North Sea waiting for emergency calls before returning to its home port. Normally, the tugboat stays close to the waters near the Island of Norderney, but in high winds of force 8 and greater, it sets course for open waters. In order to pull through a four-week period at sea, the ETV does everything it can to make the crew comfortable at the end of their shift, praising the handpicked crew.

This article was originally published on Marine & Industrial Report newspaper Vol 38 No.2 Issue last April 30,2016.