Hydromaster introduces high speed Thuster for fast craft

HYDROMASTER, renowned for its self-contained outboard propulsion units, has recently introduced its latest addition to an already existing wide range of azimuth and tunnel thrusters.

Responding to the need for a fully steerable thruster for faster craft, the company has developed a range of thrusters able to operate with vessel speeds up to 28 knots, with favourable hull designs even up to 30 knots.

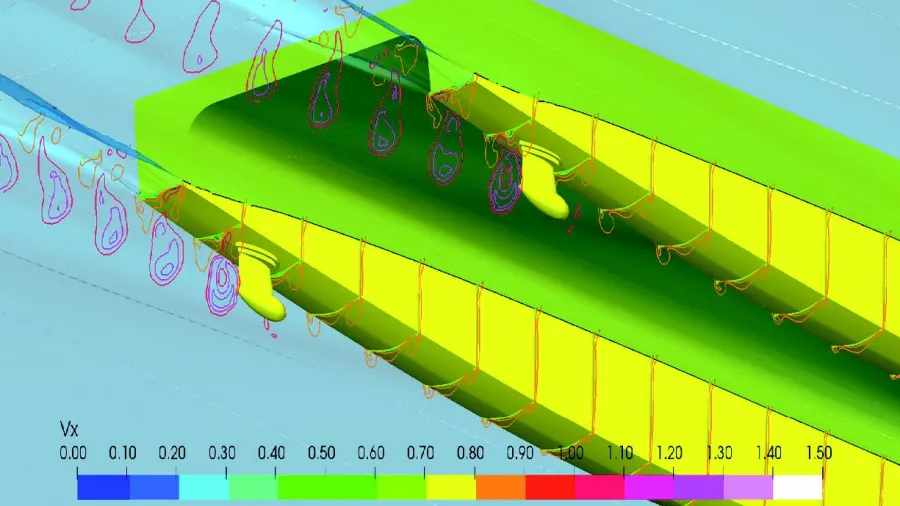

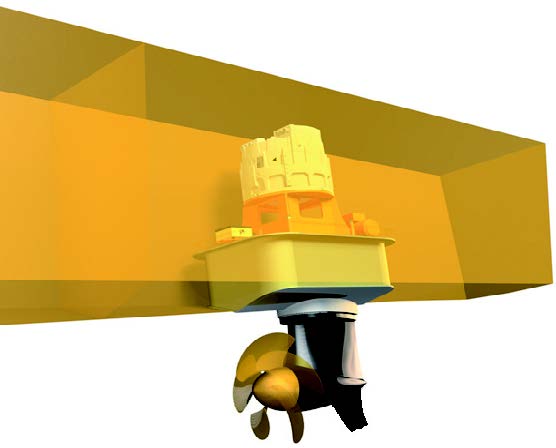

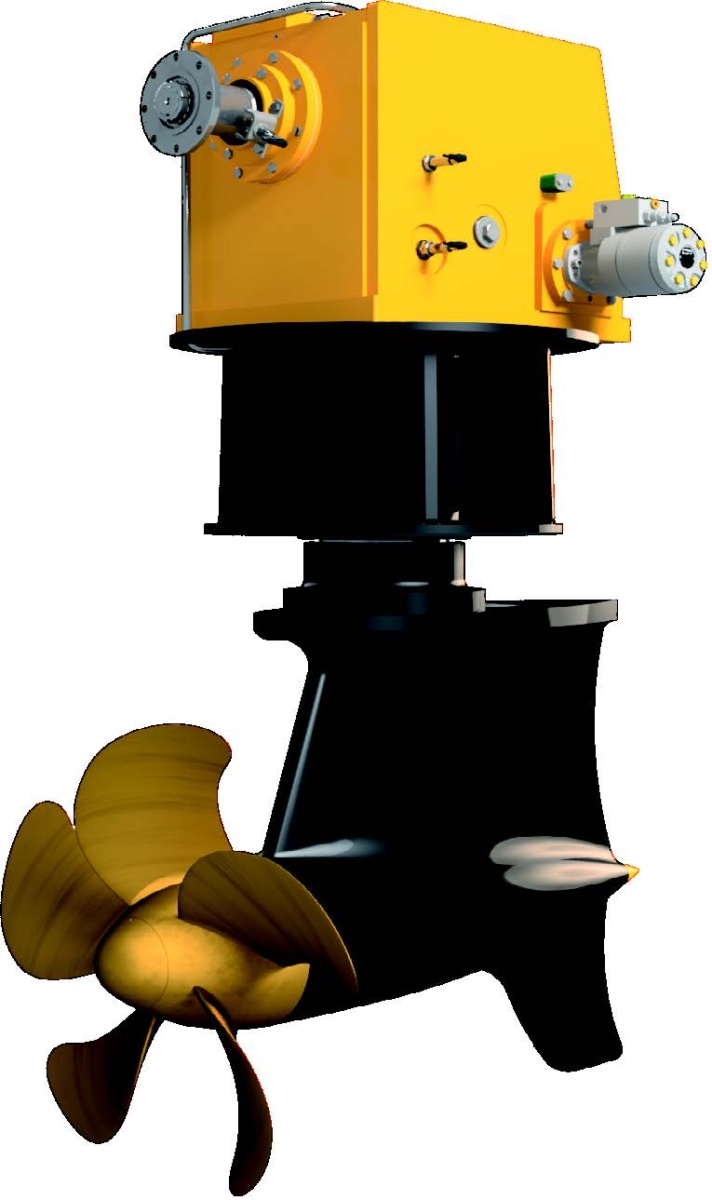

Initiated by a request from and in cooperation with Damen Shipyards, two years of research and extensive CFD studies have resulted in a genuine 360 degrees steerable thruster. It has a highly streamlined low-drag underwater body, housing a set of high grade spiral bevel gears driving an optimised pulling type highly skewed Class I propeller. It allows owners and naval architects to fit their latest commercial designs with a set of heavy duty thrusters combining superior propulsion efficiency with vessel speed and optimal manoeuvrability.

Installing waterjets or other less efficient or non-commercial grade propulsion methods will be a thing of the past and the practice of installing rudders and/or bow thrusters will become obsolete. It will provide fast craft with much desired low-speed manoeuvring, perfect for quick berthing, while approaching landing points or platforms, it will greatly reduce turn-around times.

The application seems limitless with the recent developments and increasing demand for smaller sized fast craft, like CTVs and high speed ferries. The thrusters are suitable to integrate with any hull material, including aluminium, glass fibre or carbon fibre hulls. In the wheelhouse the use of a joystick system brings actions like side-stepping, astern and other fancy moves down to a simple one-hand control.

The HYDROMASTER high speed thrusters are available in a power range up to 900 kW in a L-drive configuration with vertical mounted electric motor and full electric steering, to cater for the latest generation of electric powered vessels. For direct diesel engine driven right-angle upper gearbox Z-drive versions are available.

Gears and bearings have been sized to meet requirements of all internationally recognised classification societies, for a full continuous heavy-duty rating. The first units will be delivered shortly to Damen Shipyards and find its application on a series of high speed river cats.

This article was originally published on Marine & Industrial Report newspaper Vol 43 No.3 Issue last June 30, 2021.