Ninety months of Hull protection from Nippon paint marine

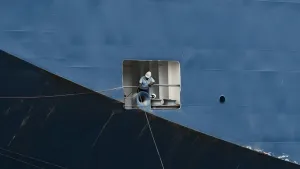

The operator of a large 72,300dwt containership delivered in 2013 found Nippon's low-friction LF-Sea hull coating to be in pristine condition after more than 30 months of service. The boxship dry docked for the first time in May 2021 after operating for seven-and-a-half years. It dry docked at a shipyard in the Far East, where Nippon Paint Marine carried out a thorough coating performance assessment.

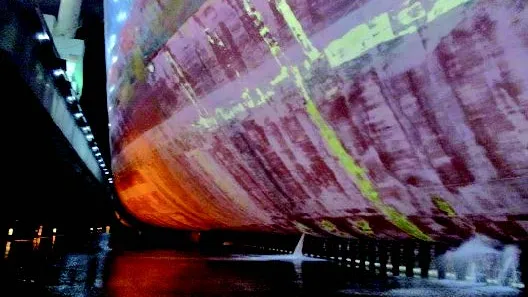

Nippon Paint Marine's inspectors reported that the vessel's 13,000m² underwater area was in "excellent condition" with no fouling observed. Only between 1 and 5% was exposed due to the polishing effect of the antifouling coat. The vessel had been moored or idle for 20% of the 90-month period.

An advanced A-LF-Sea coating applied to Yaya Goose, a 60,425dwt bulk carrier operated by Niovis Shipping, showed similar levels of performance after 60 months in operation. When the vessel dry docked last month at the Neorions Shipyard on Syros Island, Greece, Nippon Paint Marine's inspectors found the vessel's hull foul-free, with the 2016-applied coating almost intact.

Nippon Paint Marine (Europe) Deputy Managing Director Niko Yamanoue said:

"You can see from the photographs our inspectors have taken prior to high-pressure washing just how effective this coating is. The images provide clear and demonstrable evidence that investment in A-LF-Sea really pays dividend for shipowners."

No hard fouling of any sort was detected on any underwater area of the hull protected by the LF-Sea system. Nippon's hull-monitoring study showed that, on average, the vessel operated in waters of 23.6°C, at service speeds between 12 and 18 knots. Prior to entering drydock, Yaya Goose was operating at an effective median speed of 11 knots, frequently in high sea temperatures, averaging 24.8°C.

As of December 2020, Nippon Paint Marine has applied its advanced low-friction A-LF-Sea coating to 3,598 commercial vessels. The paint incorporates a patented water trapping technology to lower the hydrodynamic footprint of the hull, resulting in a stable, self-smoothing copper-silyl-acrylate copolymer designed to significantly reduce ship drag.

Nippon Paint Marine Europe Director John Drew said:

"With shipowners looking to reduce emissions through low fuel consumption, an A-LF-Sea application delivers a greener, competitive advantage to our customers."

Compared to other antifouling paint, the combined effect of Nippon Paint Marine's hydro-gel and rheology control technologies is proven to deliver up to 10% reduction in a ship's frictional resistance.

Nippon Paint Marine is a subsidiary of Nippon Paint Holdings, a top four global paint supplier. Nippon Paint has been producing marine coatings in Japan since the 1880s and has been the leader in the development of all kinds of marine paint technology, but especially antifouling paints.

Nippon Paint Marine developed and launched the world’s first self-polishing (SPC) tin-free antifouling paint (Ecoloflex) in the 1990s and followed that with the launch of the world’s first fuel-saving SPC (LF-Sea) in 2006. The company’s revolutionary Aquaterras won the Green4Sea Technology Award 2021. Aquaterras is currently the world's first and only completely biocide-free, self-polishing (SPC) antifouling paint.

This article was originally published on Marine & Industrial Report newspaper Vol 43 No.4 Issue last August 31, 2021.