Guideline in management of Gas detector cost efficiency

Total Cost of Ownership

If the acquisition of a new mobile gas measuring instrument is planned, the purchaser would usually first short-list the various market models which meet the company specified technical requirements. In a second step, attention is focused on the price. This is understandable. However, from a true economic standpoint, it is necessary to examine the "operational expenses" in addition to the "capital expenses".

The following factors are important considerations:

The sensor response time: The faster the sensor response time, the less time is required for the daily bump test, and that in turn means lower labour costs.

The duration for purging: The duration of a test procedure on the instrument Bump & Calibration station depends, among other factors, on the construction of the calibration station. How long, for example, does it take to reach the pre-set alarm level?

Test gas consumption: The test gas is a significant cost factor, so savings in this area are clearly noticeable. The test gas consumption is affected both by the sensor response time and by the gas-flow at the station.

Frequency of calibration: Some instruments have to be re-calibrated every six months, some significantly more depending on the type of sensors. There are significant differences in the various manufacturers' instructions, especially for single gas detectors.

The sensor life: Draeger sensor has a potential life span of up to 4 years if regular maintenance is observed, contributing to better total cost of ownership.

Estimate time to off-load from ship to shore for services and document results: The time spent over the entire service life of a detector adds up to a significant line item.

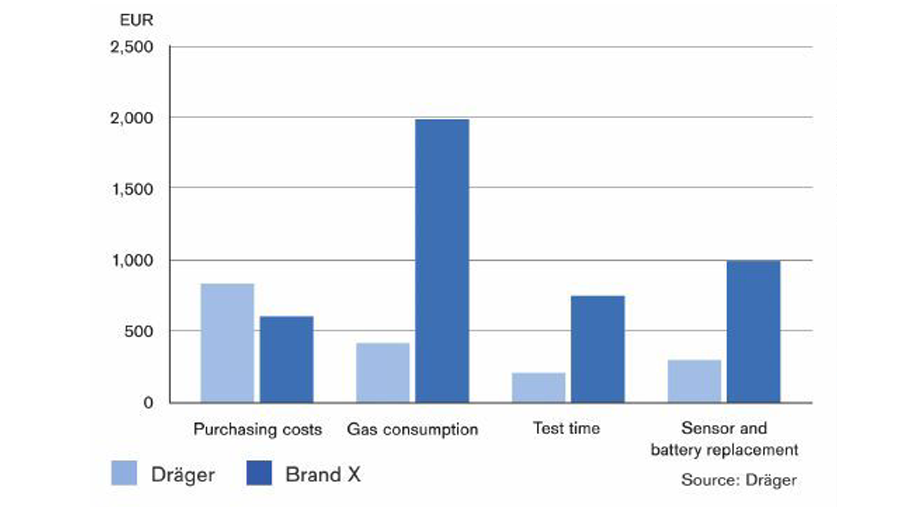

After looking at only three to four instruments, it became clear that purchase prices are broadly similar within a comparable quality class. However, the differences are much greater when it comes to operational costs. Nevertheless, in the purchasing decision, high importance is assigned to the upfront purchasing cost without giving much consideration to the operational costs which is a mistake from an economical perspective.

An Illustration of Purchasing and Operation: What Are the Potential Costs You Must Bear in Mind?

Total cost of ownership over five years using the example Draeger X-am® 2500

Maintenance and Repair

A frequently underestimated line item of operational costs is the time spent on maintenance work and eventual repair costs. "Buy cheap, pay dearly"—this saying also applies to gas measuring technology.

Good design and high-quality workmanship can contribute to significant cost savings over the years:

Robust constructions can withstand a lot even under rough conditions and that increases the service life.

High tightness, against fluids and dust for example, protects the instruments' interior.

Instruments that allow simple and intuitive operation require less instruction and training.

Instruments prone to malfunction create negative cost factors in several areas: in addition to the pure repair costs (labour time, replacement parts) the shipping and documentation effort by the ship staff must be taken into account. Unproductive workflows are a waste of money.

In addition, if instruments are frequently out of service, the limited pool of instruments onboard will lead to compromise on safety operations.

The Heart of a Gas Measuring Instrument

The heart of a gas measuring instrument is its sensor because it plays a central role in terms of the instrument's economic efficiency. "How long does the sensor last and what does a new sensor cost?"—these questions should be clarified when new instruments are purchased. A gas detector with long-lasting sensors can save up to EUR 1,000 over the total lifetime of the instrument, over 4 to 5 years.

In addition, there are ways of increasing efficiency not just in terms of the instruments themselves, but also with respect to management, maintenance and repairs.

Fleet Management and Planning

When does an instrument have to get calibrated? Available fleet management software supports the safety officers onboard with automated reminders during planning. In this way, shipping packages can be bundled, thus reducing the time involved.

Documentation and Data Management

If there is an incident onboard, insurance companies are primarily interested in whether all necessary safety measures had been accurately performed in advance.

For example, those who are unable to prove that the functional gas detectors were in operational condition within its accuracy limits, will have a problem.

Who had last used the instrument? Was it properly tested first? When was the last calibration performed? In case of emergency, the safety officer must be able to answer these questions practically at the touch of a button or face being fined by the regulatory authorities.

For example, in 2013, companies had to pay more than three million dollars in fines for violations against the rules/provisions of communicating hazards to the United States OSHA (Occupational Safety and Health Administration).

Documentation and data management has become a central challenge in almost all industries—a very time-consuming challenge. Efficient fleet management therefore also means automating the task of reporting as far as possible, so that time and thereby labour costs can be reduced. The Draeger X-dock 5300/6300 has the inherent functionality to perform bump test, calibration and document the services performed for full traceability. The total cost of ownership benefit is not just on the purchasing price of the mobile gas measurement instrument but more on the operational cost over its useful life. Taking into consideration the longevity of the sensor life, adherence to the planned maintenance program and monitoring of the instrument's operational status with proper documentation—this will give assurance of an efficient and productive gas detector performance, leading to greater safety awareness.

This article was originally published on Marine & Industrial Report newspaper Vol 42 No.1 Issue last February 29, 2020.