Shell Provides OOCL Its Integrated Lubrication Solutions for the World’s Largest Container Ship

Container Line (OOCL), one of the world’s largest integrated international container transportation, logistics, and terminal companies, has appointed Shell Marine to provide its integrated marine solutions, which include lubricants and services for OOCL Hong Kong.

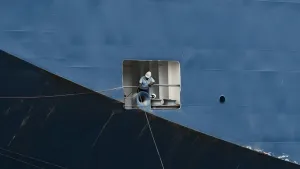

OOCL Hong Kong is the latest vessel to claim the title of the world’s largest container ship, with a capacity of 21,413 twenty-foot equivalent units (TEUs), measuring 400m in length and 59m in width. The ship is equipped with MAN Diesel & Turbo’s (MDT) G-type engines that represent the latest in two-stroke engine technology. The ship is currently plying routes between Asia and Europe.

Protecting, maintaining, and optimising marine engine performance during a period of rapid engine technology development is a complex challenge—particularly when fuel selection and vessel speed requirements are also evolving. The G-type engine design used in OOCL Hong Kong requires close oil performance monitoring and technical support. Since the containership also needs to optimise performance under very challenging operating conditions, selecting high-quality cylinder oil is of utmost importance.

Drawing on its over 30-year track record with OOCL, Shell Marine laid out its portfolio of cylinder oil options to match the owner’s operating profile and fuel grade expectations, as well as to protect the main engine against cold corrosion and optimise feed rates.

“As a supplier, we have considerable experience with MDT’s G-type engines. It was crucial that we shared our knowledge with OOCL at the outset, and that they could offer feedback in the dialogue that ultimately led to the optimal product selection,” says Jan Toschka, Shell Marine Executive Director.

In addition to Shell Marine’s lubricants, Shell LubeMonitor has been deployed onboard OOCL Hong Kong. The solution includes a cylinder oil condition monitoring service that uses both shipboard and laboratory analysis to help optimise engine performance and enable predictive maintenance.

The programme includes access to Shell tools and expert advice to help customers strike and maintain an acceptable balance between feed-rate-related cylinder oil costs and wear-related cylinder maintenance expenses. It is now enhanced with a new software package, Marine Connect, designed to transfer on-board analysis data to Shell experts easily and securely.

“Working towards the selection of the right cylinder oils is a collaborative process that needs to satisfy engine-maker approvals, as well as the client’s requirement for proven performance,” Toschka adds. “Our technical support needs to be based on the same principles, so that ship operators can monitor the condition of the oil and equipment in the field, and plan effectively when remedial action is necessary. At Shell Marine, we are committed to deliver the integrated approach which helps our customers to optimise their operations. We work closely with OEMs and with a vast variety of shipowners worldwide; this sheer breadth of experience helps when owners bring in a new engine type because we can engage with the customer at many different levels.”

Shell provides lubricants for the marine industry through its Shell Marine business. It serves over 10,000 vessels, ranging from large ocean-going tankers to small fishing boats, in over 700 ports across 59 countries. The advice and technical services provided help customers achieve maximum value from Shell’s lubricant products across all types of machinery and equipment on a ship.

Royal Dutch Shell plc is incorporated in England and Wales, with its headquarters in The Hague, and is listed on the London, Amsterdam, and New York stock exchanges. Shell companies have operations in more than 70 countries and territories with businesses including oil and gas exploration and production; production and marketing of liquefied natural gas and gas to liquids; manufacturing, marketing, and shipping of oil products and chemicals; and renewable energy projects.

This article was originally published on Marine & Industrial Report newspaper Vol 39 No.4 Issue last August 31, 2017.