Rotor sails present viable and proven option for Vessel efficiency

As shipowners look to improve the energy efficiency of their vessels in order to reduce emissions and save fuel, owners are turning to viable and off-the-shelf zero or near-zero greenhouse gas emission technologies, fuels and energy sources in a bid to ensure their vessels remain compliant with IMO regulations while staying competitive.

Wind-assisted propulsion systems are one of the leading technologies that can enable vessels to drastically cut their emissions output. This is crucial for commercial vessels as they look to comply with the IMO’s upcoming Carbon Intensity Index (CII) deadline of January 2024, while meeting regional requirements such as the EU Emissions Trading System (ETS) that will be extended to ships of more than 5,000 gt and above next year.

“With shipowners and managers looking to minimise their carbon emissions while maintaining full operations, Rotor Sails are now acknowledged as an established and proven way of providing auxiliary propulsion and reducing fuel consumption,” said Kim Diederichsen, CEO at Anemoi Marine Technologies, the UK-based developer and provider of Rotor Sails for the global shipping industry.

“Wind propulsion has found its place in modern shipping. With pressure growing on ship owners to go green, Rotor Sails are a visible, viable and cost-effective decarbonisation technology that enable vessels to save fuel and comply with emissions regulations,” he added.

Rotor Sails, which have been highlighted by the IMO as one of the leading zero-carbon technologies on the market, provide substantial alternative propulsion for modern vessels. Relying on an aerodynamic phenomenon known as the ‘Magnus Effect’, these tall cylinders create a forward thrust for the vessel that enables it to reduce power from its main engines, minimise its fuel consumption and cut its carbon output. Indeed, data from modern Rotor Sail systems has shown that the technology can achieve fuel savings of up to 30%.

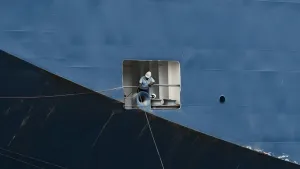

Rotor Sails are also incredibly easy to install. They do not require any wholesale changes to the vessel’s structure or drydocking, making them ideal for retrofitting, and each Rotor Sail can be installed in a single crane lift and connected to the foundation on the ship’s deck. Crucially, the technology is viable for almost all vessel types and can be fitted with bespoke deployment systems, including folding the sails from vertical or moving them on a rail system along or across the deck, to minimise the impact on cargo loading and unloading operations, and avoid low-clearance bridges.

Both bulkers and tankers are ideally suited to Rotor Sail technology. Their large, open deck space allows for multiple Rotor Sails to be fitted in a configuration that can take advantage of plentiful wind supplies and maximise savings. The available space means larger sizes and quantities of Rotor Sails can be installed to maximise performance. For example, data from Anemoi has shown that a 310,000 dwt VLCC trading the Bonny-Ningbo route and fitted with five Rotor Sails could save over 13% in annual fuel consumption and emission reductions, which equates to over 1,600 tonnes of fuel and around 5,000 tonnes of carbon saved each year.

The UK-based developer has recently showcased the benefits of Rotor Sails for bulk carriers with the installation of three sails, as well as Anemoi’s patented rail deployment system, on the 82,000 dwt Kamsarmax TR Lady earlier this year. Initial data from the vessel’s first voyage indicated that the vessel can expect to save around 10% of fuel and emissions annually as a direct result of the Rotor Sails.

“The initial results we have seen from the TR Lady project so far are incredibly positive. We will continue to assess the performance of the vessel and the Rotor Sails over the coming months, and we expect to continue to see positive results for our environment,” said Diederichsen.

Meanwhile, in November, Anemoi announced it had partnered with Brazil’s Vale to install five Rotor Sails onboard the world’s largest ore carrier, Sohar Max, a 400,000 dwt VLOC, to improve the energy efficiency of the vessel: a major step in reducing the carbon footprint related to the maritime transportation of iron ore.

Buoyed by recent success, Anemoi has continued to expand its technology to other vessel types. In October, it announced it had entered into a Joint Design Cooperation Agreement with Hudong-Zhonghua Shipbuilding Group to design Rotor Sails for LNG carriers to develop a new generation of efficient and environmentally friendly LNG carrier designs.

“By partnering with leading shipyards around the world, we can ensure that we are playing our part to create a brighter and cleaner future for the maritime industry. More shipowners around the world are realising the benefits of Rotor Sails as a means to reduce their carbon footprint and this technology, combined with other eco-friendly technologies and low-carbon fuels, can ensure we all head towards net zero.” Diederichsen noted.

This article was originally published on Marine & Industrial Report newspaper Vol 45 No.6 Issue last December 31, 2023.